Optimizing Shipping Load Patterns – Pallet Loading Patterns

Home » Optimizing Shipping Load Patterns – Pallet Loading Patterns

Pallet Loading Patterns – Litco Can Help!

Get a Complete Blocking / Bracing / Dunnage System FREE for Your First Load, Plus Optimized Load Planning Diagrams

Our FREE Load Optimization Software Service puts you in control to comply with regulations in loading intermodal cargo containers for over-the-road trucking and railcar transit. With an optimized load diagram built using TOPS software, Litco’s shipping experts can help you maximize cubic feet per load while minimizing the costs of inflatable and cardboard dunnage, keeping your products safe, secure and damage-free.

Your First Shipment Travels with FREE Void Fill and Dunnage Products from Litco’s Advanced Product Damage Prevention Toolset

Even palletized loads that seem stable will lean or fall over in the trailer based on lateral forces (side-to-side shifts) put on cargo during transportation. Optimizing the pallet loading patterns of your SPECIFIC FREIGHT whether you ship via 53 ft. trailer, railcar or intermodal container, means juggling 3 separate issues:

- Properly distributing weight within the trailer

- Maxing out the cubic volume allowable based on the weight limitations

- Ensuring sufficient and appropriate dunnage void fill to effectively block and brace the cargo against shifts that will occur during transit and in handling.

Weight as the First Consideration

When filling an intermodal container or truck with palletized product or other unitized loads, there are several variables that affect your optimized loading methodology. The first and likely most significant variable is weight. If the product you are shipping is heavy, the capacity of the trailer or container will limit your loading options.

A typical (empty) trailer with tractor attached, including diesel fuel weight, can be about 35,000 to 36,000 pounds.

The maximum legal gross weight to drive without any special permits in the US is 80,000 pounds.

This means that a full truckload could carry 44,500 pounds max cargo weight. This weight calculation needs to include product, packaging, dunnage bags, and pallets. If you were being conservative, you could plan to carry 42,000 pounds, allowing for an extra 1,500 pounds over product weight.

PRO TIP: If you are looking for a lighter-weight pallet, economical enough to use for one-way shipping and ISPM 15 (export-ready) compliant, check out Litco’s molded wood pallets.

Weight considerations for shipping intermodal

Maximum Weights, Weight Distribution, and Center of Gravity

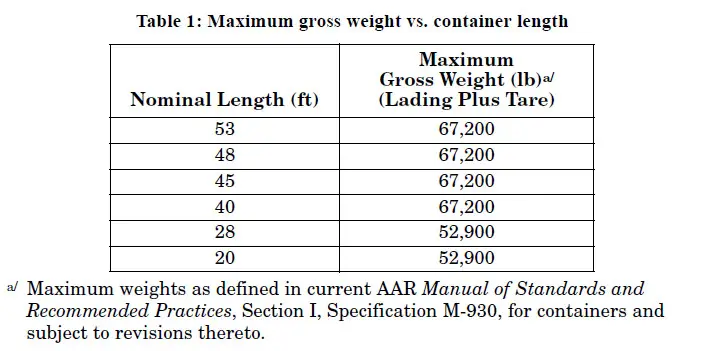

A. The load weight must not exceed the limit as stated on the manufacturer’s plate. Combined weight of trailer and lading may not exceed 65,000 lb.* Combined weight of container and lading may not exceed the weight specified below for the length of container being loaded:

*Maximum weights as defined in current AAR Specification M-931-04 for trailers (effective 2/1/04), and subject to revisions thereto.

**Maximum weights as defined in current AAR Specification M-930-08 for containers (implemented 10/2008), and subject to revisions thereto.

B. Lading weight in trailers or containers must be evenly distributed both crosswise and lengthwise, and combined weight of lading and trailer or container must conform to all federal, state, provincial, and local regulations and transportation service requirements used at origin and to final destination. (See Illustrations 1, 2, 3, and 4.)

C. Combined center of gravity (measured from top of rail) of car, trailer or container, and load is not to exceed 98 in.

Weight Distribution is Critical. Loading a trailer so it will not be overweight on any axle.

The problem OTR truckers most often run into is not the total gross weight being over 80,000 – it’s having the truck loaded improperly so it is overweight on one of the tandem axles.

Part of the TOPS program helps your warehouse truck loading team properly distribute the cargo from front to back in the trailer based on weight.

As a starting point, it is important to know 3 things:

- How much does your load weigh?

- Does that include the pallets and packaging?

- How many pallets will comprise the whole load?

NOTE: If your trucking company is stopped for illegal weight distribution – even if the entire load is below weight limits – the shipment will need to come back to your warehouse for a re-load, causing extra unpaid work for both the manufacturer and the trucking company.

Step-by-Step 53 ft Trailer Pallet Loading Diagram and Other Configurations

By inviting a Litco damage prevention expert to work with you, you are getting access to industry-leading load configuration tools created by TOPS Engineering. MaxLoad Pro is a cargo load planning, container loading, freight calculation and cube optimization software. It can calculate accurate container and truck load plans by determining ideal ways to palletize your goods and, using intelligent loading algorithms and extensive stacking rules, develop a plan for you to follow so you can load mixed sized products into containers and vehicles. Litco Manufacturing offers various product protection options like corner protectors, anti-slip rubber mats, and load separators.

AN EXAMPLE: One technique that can help create a more stable load and economize on space is loading pallets in a pinwheel configuration. Because the pallets most frequently used measure 40″x 48″, sometimes, in a 96″ wide trailer, you can turn one of the pallets 90 degrees, allowing two pallets to fit next to each other, hence the term “pinwheel.” Pinwheel loading creates additional stability by interspersing pallets with different load orientations.

Get a Complete Blocking / Bracing / Dunnage System FREE for Your First Load,

Plus Optimized Load Planning Diagrams