According to National Safety Council, fork lift accidents result in an average of 101 fatalities and 94,570 injuries each year. Although lift trucks are a necessary to maintain the efficient flow of raw materials and finished goods through manufacturing facilities, their use poses risks to both their operators and pedestrian traffic in your plant. This article explains how pallet design influences fork lift traffic in manufacturing facilities and distribution centers and explores why presswood pallets may be a safer, more efficient alternative to conventional pallets.

One of the most prominent design features of presswood pallets is evident the moment a truck load of Litco pallets arrives on your receiving dock. Unlike conventional wooden pallets, presswood pallets are nestable, which allows greater quantities to ship with each trailer load. The chart below illustrates the required number of truckloads for customers ordering various quantities of medium duty pallets:

TABLE ONE: Truck Load Comparisons: Wooden Versus Presswood Pallets

|

Annual QTY of Pallets |

Trucks of Wooden at 580/Truck Load |

Trucks of INCA at 1280/Truck Load |

Difference |

% of Difference |

|

10,000 |

17 |

8 |

9 |

53% Less |

|

25,000 |

43 |

20 |

23 |

53% Less |

|

50,000 |

86 |

39 |

47 |

55% Less |

|

100,000 |

173 |

79 |

94 |

55% Less |

|

200,000 |

345 |

156 |

189 |

55% Less |

As the chart demonstrates, the numbers of trucks passing through receiving docks is reduced by half simply by choosing a pallet with nestable design features. Unloading fewer trailers translates to reduced lift truck traffic, which in turn results in improved efficiencies and a safer workplace. The reduced lift truck traffic found on the docks also extends to storage in the receiving area. The nestability of presswood allows drivers to transport more pallets with 64% fewer trips and decrease the probability of a forklift related accident the same amount, as shown by the chart below:

TABLE TWO: Lift Truck Trips To Load Pallet Dispensers

Comparison: 48” x 40” GMA Style VS. LITCO’s INCA Nestable Presswood Pallets

(Based on 18 wooden pallets per stack and 50 presswood pallets per stack)

|

Annual QTY of Pallets |

# of Lift Truck Trips GMA Style |

# of Lift Truck Trips Presswood |

Difference |

% of Difference |

|

10,000 |

556 |

200 |

<356> |

64% Less |

|

25,000 |

1389 |

500 |

<889> |

“ “ |

|

50,000 |

2778 |

1000 |

<1778> |

“ “ |

|

100,000 |

5556 |

2000 |

<3556> |

“ “ |

|

200,000 |

11,111 |

4000 |

<7111> |

“ “ |

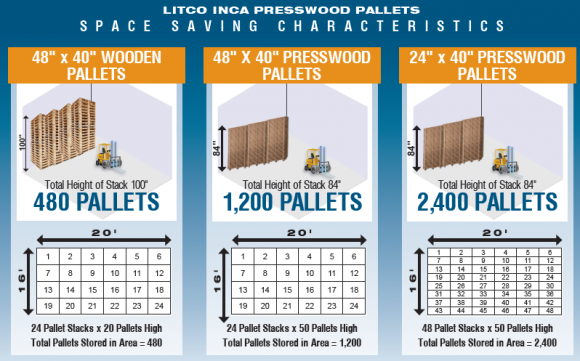

The nestability of presswood pallets also reduces receiving area congestion and improves driver site lines due to a smaller footprint when compared to conventional pallets:

Nestable pallets can also reduce fork lift traffic from shipping and receiving areas to pallet dispensers. A typical pallet dispenser accommodates eighteen 48” x 40” conventional GMA pallets. By comparison, this same pallet dispenser accommodates fifty nestable Inca pallets. More pallets in your dispensers means fewer lift truck trips made from storage through your production areas to shipping and packaging lines. The advantages of advanced pallet design go beyond mere product protection; selecting the proper pallet can reduce lift truck traffic, increase driver and packaging line efficiency, and enhance plant safety.

Safety and efficiency aren’t mutually exclusive goals and making the proper pallet choice may contribute to a plant environment we can all take pride in. To learn more about labor and space savings as well as reduced lift truck traffic associated with presswood pallet use, contact an Export and Domestic Pallet Solution Specialist at Litco International, Inc. for more information.

Litco international, Inc, based in Vienna, Ohio, is North America’s leading source of International Pallet Solutions to ease the pains of export and domestic shipping. Litco’s Inca Presswood pallets are ideal for export applications because they are pest free and therefore, do not need to be regulated by IPPC-ISPM 15. They are a complement to any sustainment program and are Cradle to Cradle Certifiedcm Silver by MBDC.

Litco also offers a full range of pallet types, core plugs for roll ends and load securement products to move products safely through the most demanding supply chains. Litco was established in 1962 and ships from facilities located in Dover, OH, Warren, OH, Sardis, MS and Wellford, SC. For more information, visit www.litco.com/.